A high-performance anechoic chamber with excellent traceability and reproducibility is of utmost importance in EMC (electromagnetic compatibility) testing. The anechoic chamber is no longer a simple evaluation facility but has evolved into a powerful tool for product development.

What Is an Anechoic Chamber?

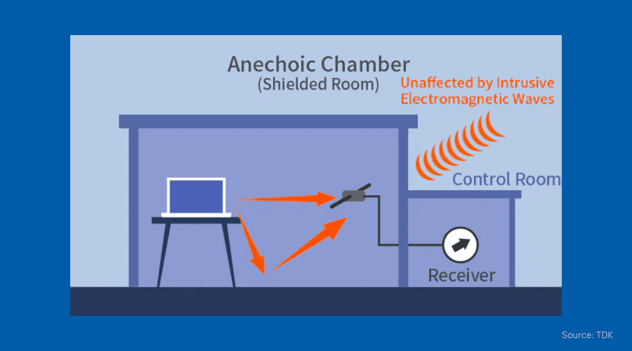

The word "anechoic" means simply "without echo." The anechoic chamber is a specialized and shielded space designed to resist electromagnetic waves while suppressing the emission of such waves to the outside world. Originating in the early 1950s, anechoic chambers were initially used for experiments and research on radio equipment and antennas. Since the implementation of extensive noise regulations in the 1980s, these chambers have been increasingly used to evaluate noise emissions of electronic equipment.

History of the Anechoic Chamber

Anechoic chambers were first named by Leo Beranek, a notable expert in acoustics. Originally, these chambers were developed as acoustic anechoic chambers. However, as time progressed, the scope of the term was broadened to include RF and sonar anechoic chambers as well. These specialized chambers have the capability to block external noise and suppress reflections caused by electromagnetic waves.

An anechoic chamber is shielded entirely with metal and has radio wave absorbers covering the surrounding walls—five sides (walls plus ceiling) or six sides, including the floor. The size of the anechoic chamber and the type of radio wave absorber to be used are determined by the size and purpose of the electronic equipment being evaluated; 10 m and 3 m anechoic chambers are utilized in EMC testing.

In order to ensure the reproducibility of EMC test results, parameters known as site attenuation are used as a benchmark. This standard indicates whether an anechoic chamber provides an acceptable electromagnetic environment for EMC testing and requires that transmission losses—between the transmitting/receiving antennas and the measuring antennas—fall within specified limits.

Since the EMC Directive went into effect in 1996, noise regulations have been extended to cover large and heavy-duty machinery. With all kinds of household appliances now equipped with wireless technology, products are more complex than ever. As a result, the demand for 10 m anechoic chambers is growing rapidly. Radio wave absorbers for 10 m anechoic chambers are required to have a wide bandwidth and absorption level of at least 20 dB. To achieve these conditions using only a dielectric absorber, the absorber would need to be longer than 5 m, requiring a huge building.

For this reason, professors Kunihiro Suetake, Yoshiyuki Naito, and Yasutaka Shimizu of the Tokyo Institute of Technology developed a composite absorber combining ferrite and dielectric materials in the 1960s. Since then, short-length composite absorbers have become mainstream in 10 m anechoic chambers.

The World's Oldest Wedge-Based Anechoic Chamber

According to Bell Labs, the Murray Hill anechoic chamber, which was constructed in 1947, is recognized as the world's oldest wedge-based anechoic chamber. The internal dimensions of the chamber are approximately 9.1 m in height, 8.5 m in width, and 9.7 m in depth. The exterior walls are made of cement and brick and are about 0.9 m thick to minimize external noise.

The term "anechoic" refers to the absence of echoes. To absorb echoes or reflections, the Murray Hill chamber is equipped with large fiberglass wedges mounted on its interior surfaces. These wedge-shaped absorbers measure 1.37 m long and 0.6 m square at the base. The anechoic chambers of today commonly use the same alternating wedge pattern found in the Murray Hill chamber. The wedge shape was selected to achieve an "impedance match" between the absorber and the surrounding air. It can also be thought of as a waveguide where all incident acoustic energy is internally reflected into the wedge. The alternating pattern was chosen to provide more uniform angular absorption. Above 200 Hz, the chamber absorbs more than 99.995% of the incident acoustic energy. The Murray Hill chamber was once recognized in the Guinness Book of World Records as the world's quietest room.

The Rising Importance of Anechoic Chambers

Electronic equipment, wireless devices, and communication systems generate a variety of electromagnetic waves. The electromagnetic waves generated by one device may negatively affect nearby devices. EMC (electromagnetic compatibility) addresses two issues:

1. Emissions: the need to suppress the generation of EMI (electromagnetic interference).

2. Immunity: the need to resist EMI generated by other devices.

There is an urgent need for countermeasures, starting early in the product design and development stages, that allow a wide variety of electronic, wireless, and communication devices to coexist.

One way to measure the electric field strength of electromagnetic noise generated from electronic devices is at an open-air test site (OATS). However, the disadvantage of outdoor testing is that it is easily affected by adverse weather conditions and is susceptible to electromagnetic waves present in the surrounding environment.

Additionally, because extremely strong electric fields are produced during immunity tests, they cannot be conducted at an OATS due to radio communication regulations. Therefore, the anechoic chamber is becoming increasingly important as a facility that can perform such tests with high reliability and efficiency.

Anechoic chambers have many advantages that make them essential in various fields such as acoustics, radio frequency engineering, and electromagnetic compatibility testing:

- They are unaffected by intrusive electromagnetic waves.

- They provide a stable test environment.

- They contain electromagnetic interference.

- Tests with electric solid fields (immunity tests) can be performed.

- Tests can be kept confidential.

Moreover, anechoic chambers enable tests with strong electric fields, also known as immunity tests, which cannot be performed at outdoor test sites due to radio communication regulations. With anechoic chambers, the electric field strength of electromagnetic noise generated from electronic devices can be accurately measured, allowing for the early detection and suppression of electromagnetic interference.

In summary, anechoic chambers offer multiple benefits, including stable testing environments, immunity testing capabilities, and the ability to conduct tests confidentially, making them essential in various fields such as acoustics, radio frequency engineering, and electromagnetic compatibility testing.

Ferrite: The Predominant Radio Wave Absorber Material

Radio wave absorption materials are classified into three categories: magnetic, dielectric, and resistive. Examples of magnetic absorbing materials include sintered ferrite (hereafter referred to as “ferrite”), soft magnetic alloys, and carbonyl iron compounded with resin. Ferrite, the most common material applied to the walls of anechoic chambers for EMC testing, causes magnetic loss in high-frequency AC magnetic fields. Ferrite-based radio wave absorbers make use of this property. Examples include the absorption of television waves, which are converted to heat to reduce ghosting effects seen on TVs caused by waves reflected off high-rise buildings, and to prevent false images on airborne radar. Thanks to production techniques accumulated over the years, ferrite is being developed further as a major radio wave absorber for EMC testing in anechoic chambers.

Gaps are placed between ferrite tiles to control their thickness, which optimizes radio wave absorption properties and helps maintain integrity and safety as a wall material. Ferrite tiles are designed for optimal radio wave absorption according to the specific angle of incidence of radio waves.

Inside the Quietest Place on Earth at Orfield Laboratories, USA

Orfield Laboratories' anechoic test chamber in Minneapolis, Minnesota, USA, holds the world record for the quietest place on earth. This anechoic chamber has been designed to facilitate precise measurements of sound levels produced by different test objects.

It features a large chamber made of masonry and concrete, lined with 10.5 cm–thick steel plates. Within this chamber is a smaller steel chamber, supported by vibration-absorbing springs. The interior of the space is covered with a layer of heavy insulation and fiberglass wedges that extend 85 cm into the space, including on the floor, where users must stand on a suspended mesh. The usable area inside the chamber measures 3.7 × 3.1 × 3.52 m. As of 19 November 2021, the ambient sound level inside the chamber was recorded at an astonishingly low –24.9 decibels.

Types of Anechoic Chambers

Anechoic chambers are available in two basic types: acoustic chambers and shielded rooms.

Acoustic Chambers

Anechoic chambers are frequently utilized in the field of acoustics for conducting experiments under ideal "free field" conditions, where sound waves are not reflected back to the source. This type of chamber enables researchers to measure the transfer function of a loudspeaker or the directivity of noise radiation from industrial equipment with high accuracy. Due to the absence of reflected signals, sound energy travels only away from the source within an anechoic chamber, resulting in an environment that can be incredibly quiet, typically exhibiting noise levels between 10 and 20 dBA.

RF Shielded Rooms

Anechoic chambers also play a significant role in the field of radio frequency (RF) engineering by providing a controlled environment for testing antennas, radars, and various wireless communication devices.

While the internal layout of an RF anechoic chamber may resemble that of an acoustic chamber, it utilizes radiation-absorbent material (RAM) instead of acoustically absorbent material to cover the interior surfaces. This RAM enables the chamber to absorb electromagnetic waves instead of acoustic waves, creating an environment where radio signals are not reflected. RF anechoic chambers are typically used to investigate antenna radiation patterns, gain, efficiency, and other performance metrics.

The design of antennas has become increasingly complex as modern devices incorporate multiple wireless communication technologies, including cellular, WiFi, Bluetooth, RFID, and GPS. As a result, the challenges in designing antennas with the desired performance characteristics have grown significantly.

Full Anechoic Chambers

A full anechoic chamber is designed to absorb energy in all directions, requiring correctly shaped wedges to cover all surfaces, including the floor. A mesh grille is placed above the floor to provide a surface for walking and equipment placement, and the chamber itself extends below floor level. The mesh floor is damped and floating on absorbent buffers to isolate it from outside vibration or electromagnetic signals.

Semi-Anechoic Chambers or Hemi-Anechoic Chambers

The terms "semi-anechoic" and "hemi-anechoic" are sometimes used interchangeably, but some definitions distinguish between the two based on the type of floor. Some uses consider "semi-anechoic" to have an ideally reflective floor, while "hemi-anechoic" simply has a flat untreated floor. Other definitions distinguish them by size and performance, with "semi-anechoic" being a retrofitted room and "hemi-anechoic" being a purpose-built, larger room with better anechoic performance. Recording studios often use semi-anechoic chambers.

Examples of Anechoic Chambers

Here are a few examples of anechoic chambers:

-

Anechoic chamber at the Indian Institute of Science (IISc) in Bangalore, India: This chamber is the largest chamber in India used for research into audio and acoustic technologies, including noise reduction and speech intelligibility.

-

TDK semi-anechoic chambers: TDK's baseline semi-anechoic 3 m chambers are designed to provide an optimal environment for radiated emissions and radiated immunity measurements.

-

European Space Research and Technology Centre (ESTEC) in the Netherlands: ESTEC has a large anechoic chamber used for testing space equipment and satellites. Now they are adding an antenna and radio-frequency payload test chamber.

-

Benefield Anechoic Facility (BAF): The BAF is a ground test facility used to investigate and evaluate anomalies associated with electronic warfare systems, avionics, tactical missiles, and their host platforms. It is currently the world's largest anechoic chamber.

-

Anechoic chamber at KTH Royal Institute of Technology in Sweden: This chamber is used for antenna characterization and other educational and research projects.

These are just a few examples of the many anechoic chambers that exist around the world and are used for a variety of purposes.

Conclusion

The use of anechoic chambers is becoming increasingly important in today's world, where electronic equipment and wireless devices generate a variety of electromagnetic signals. These chambers provide a controlled environment for testing and evaluating electronic equipment while suppressing the emission of electromagnetic waves into the outside world. The history of anechoic chambers dates back to the 1950s, and since then, they have evolved into a powerful tool for product development.

The demand for anechoic chambers is rapidly growing, and their importance is rising as they provide high reliability and efficiency in conducting tests with strong electric fields. As an EMC expert, I encourage readers to learn more about the different types of anechoic chambers, their uses, and the benefits they offer for designing and evaluating electronic devices.